No Glass with all the Class

No Glass with all the Class

Click on the following product names and get exclusive access to our product specifications.

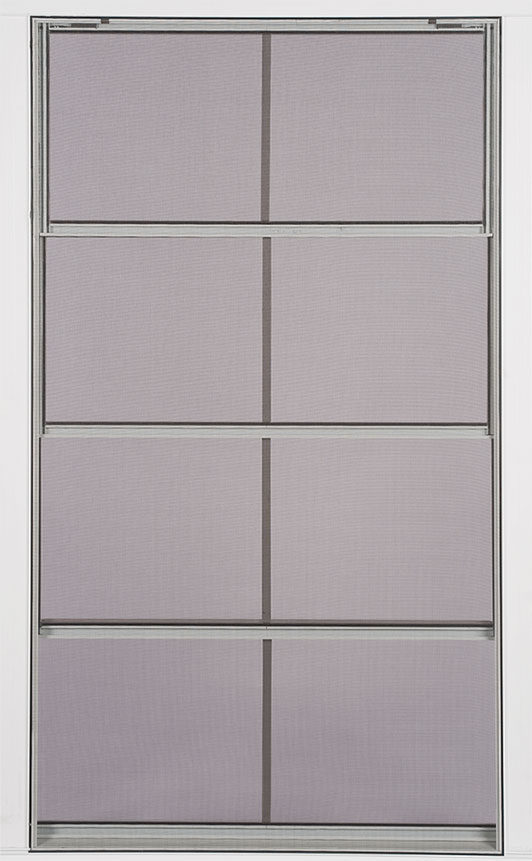

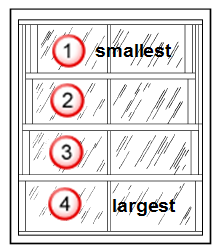

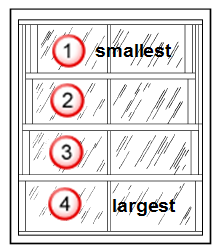

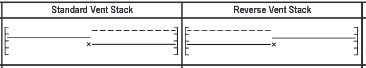

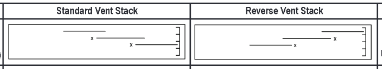

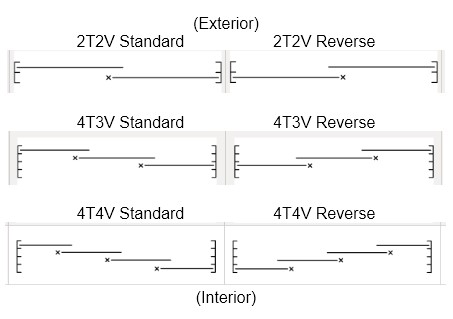

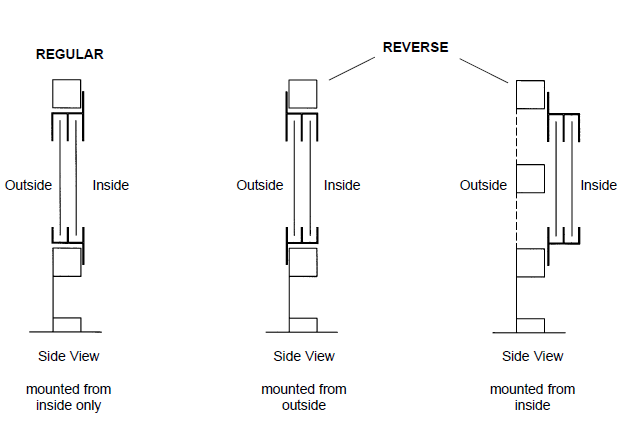

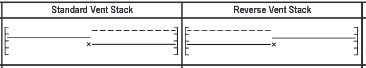

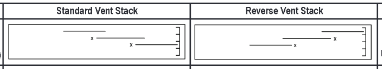

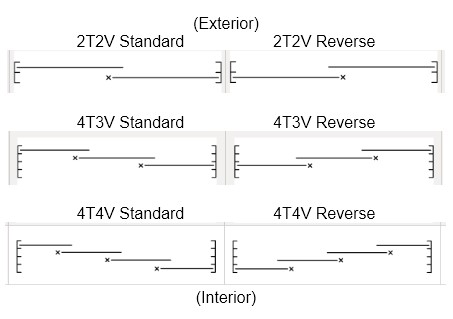

Note: All Eze-Breeze products are viewed inside looking out.

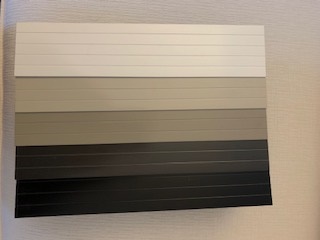

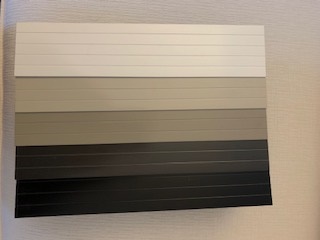

White

Bronze

Sandstone

Black

Pebble Khaki

Clear

Bronze

Smoke Grey

Muskoka Blue

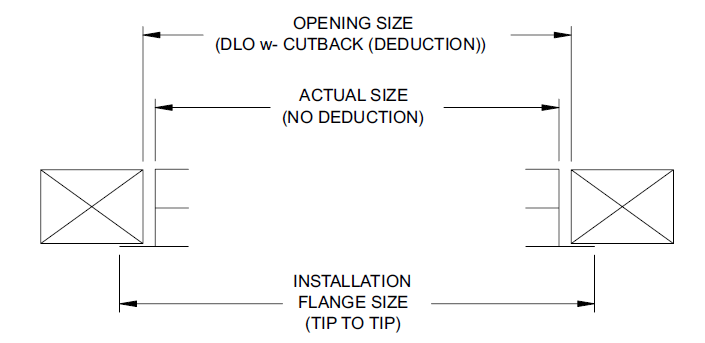

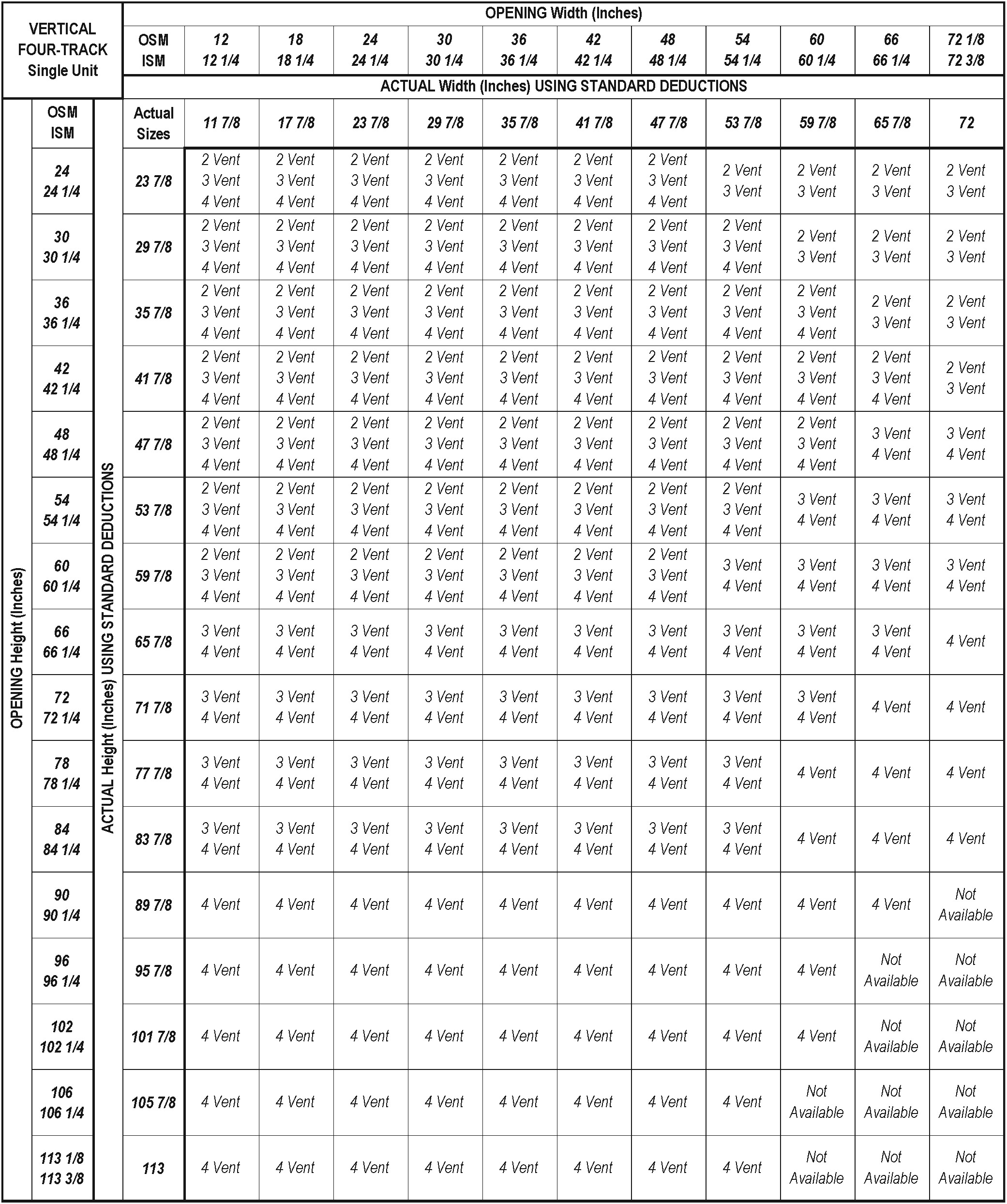

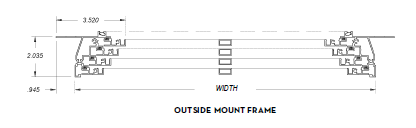

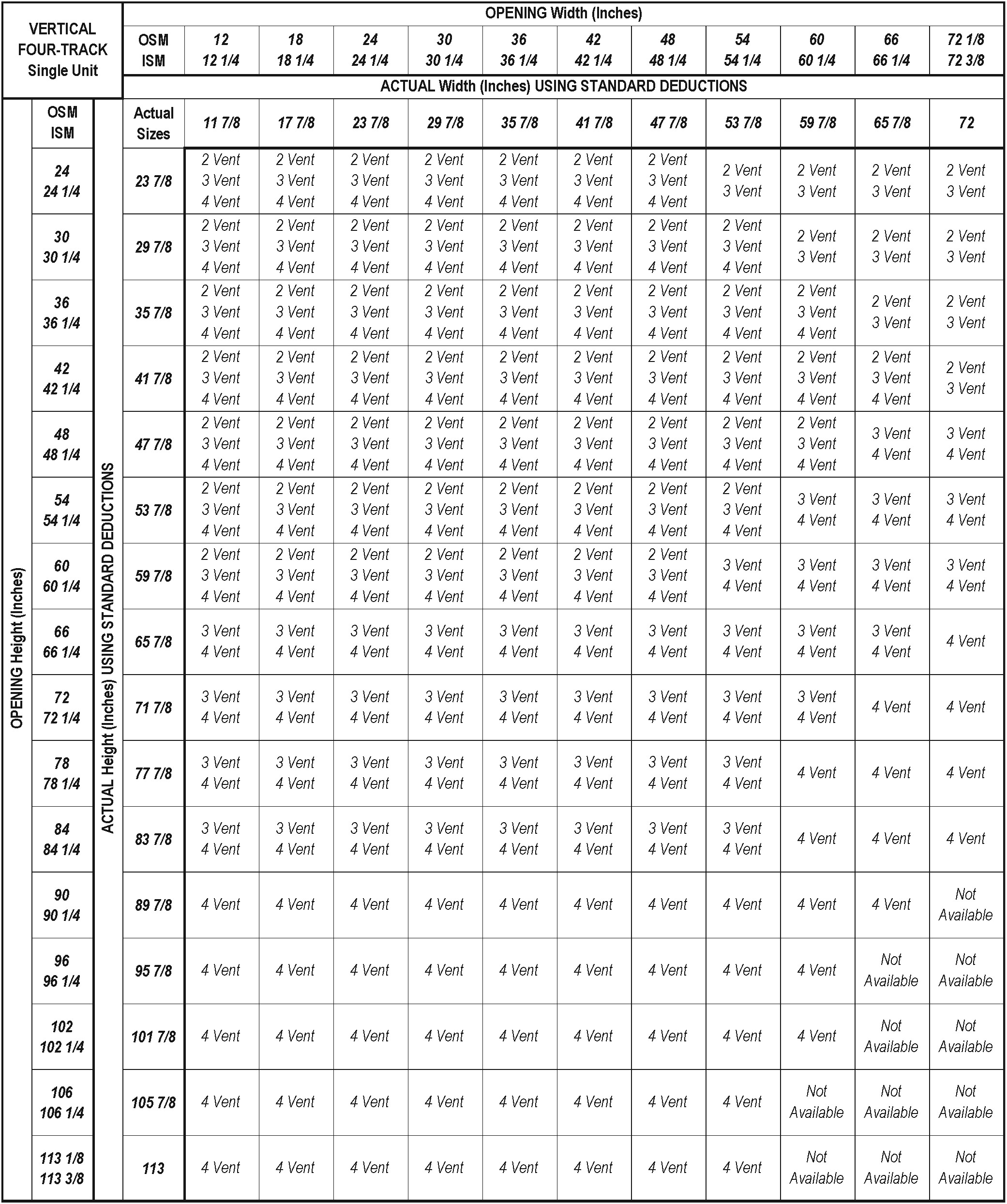

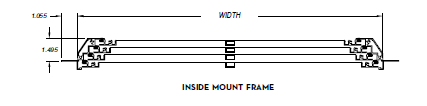

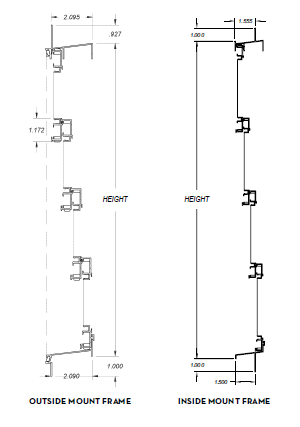

"Opening Size" measurements are preferred. All sizes must be given (width x height in inches) - see product specifications for standard cutbacks (deductions) or order by actual unit size.

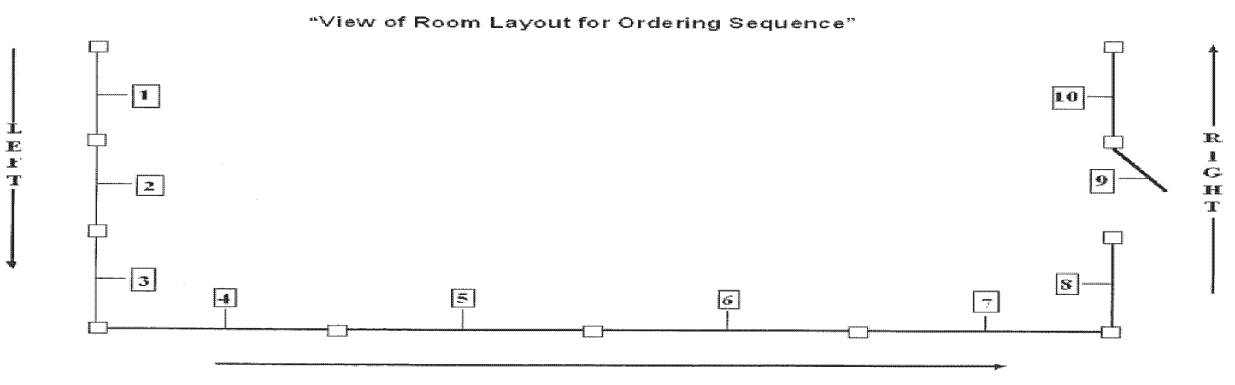

Upon request, PGT will number the units in the same order they are given thus avoiding confusion during installation. When measuring, start at one end and work your way around the room, numbering each opening in sequence and give your Customer Service Representative the unit sizes in the same order they were measured.

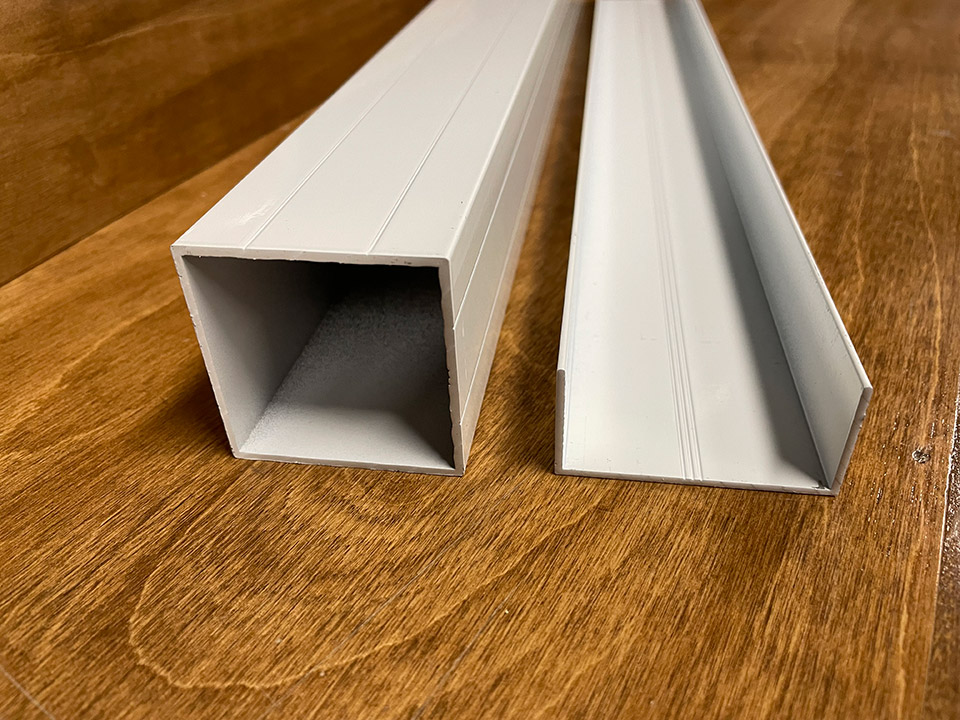

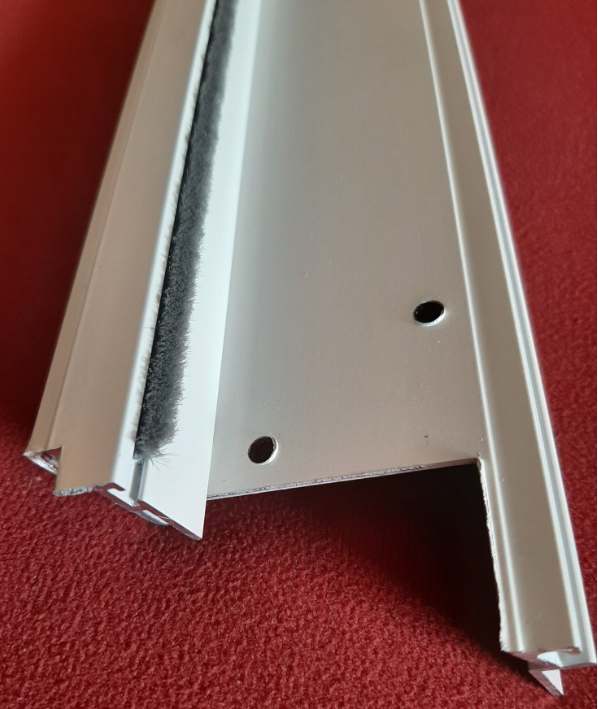

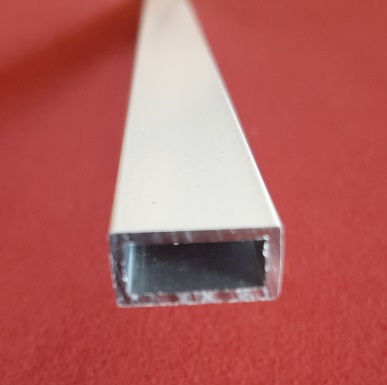

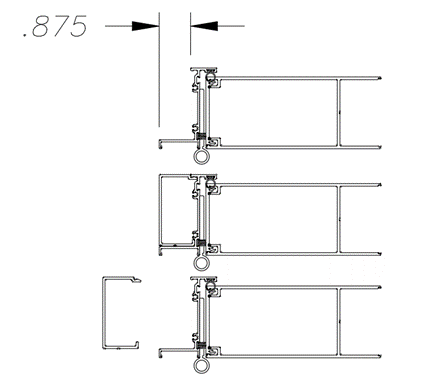

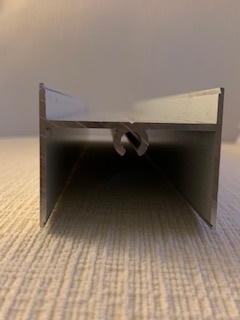

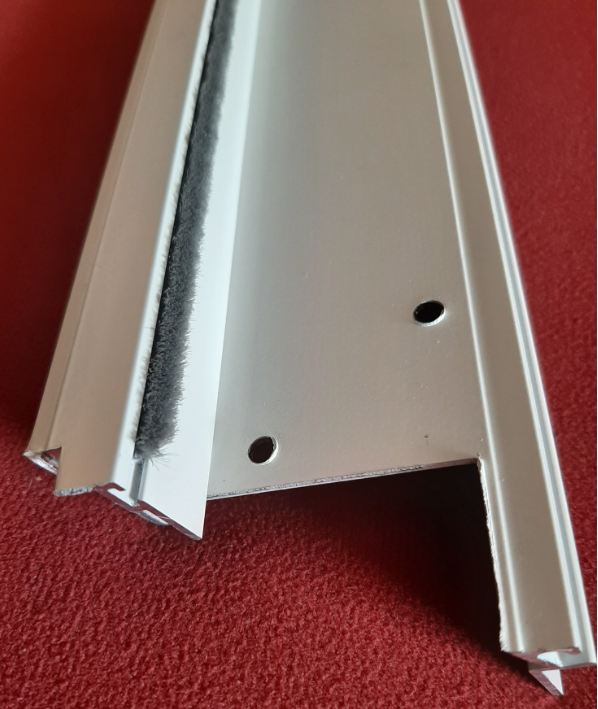

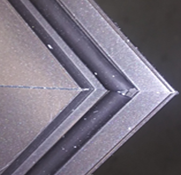

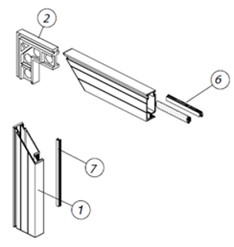

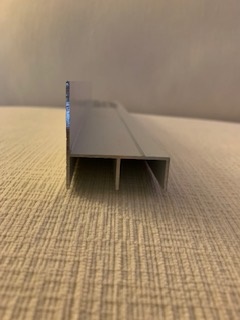

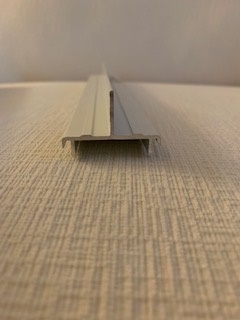

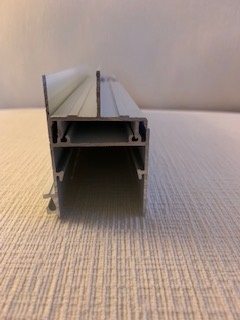

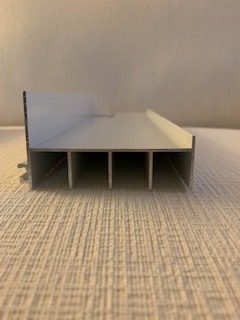

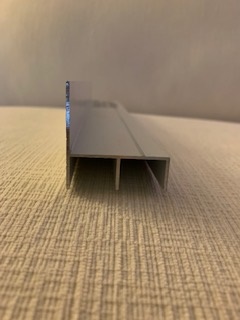

Mull Post C-Channel

Mull Post fit into a C-Channel

Mull Post fit into a C-Channel vertically

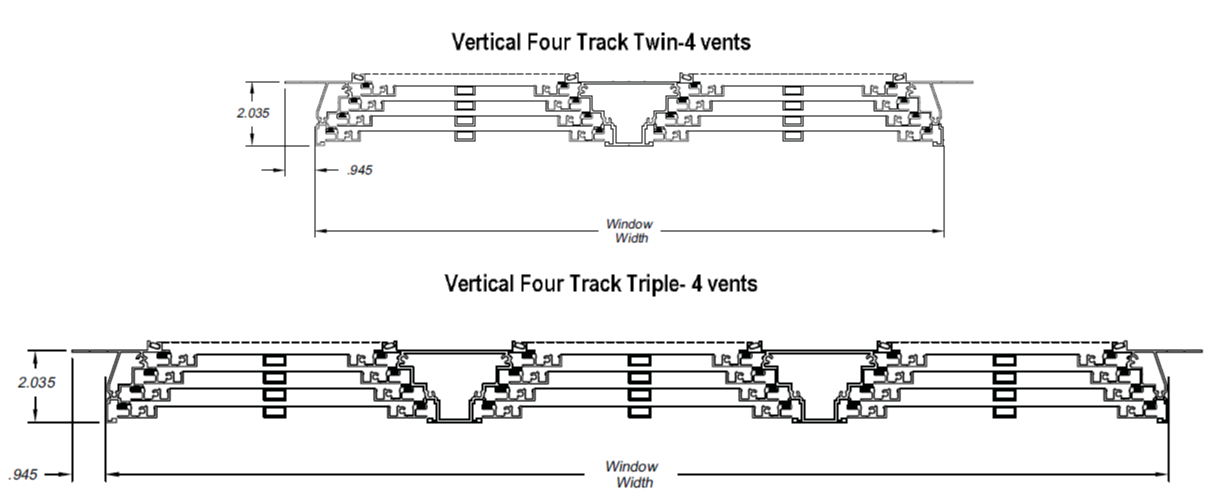

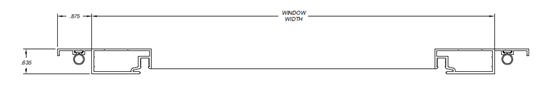

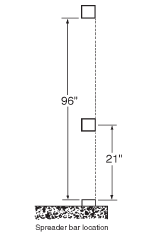

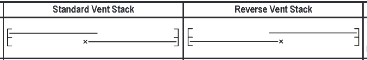

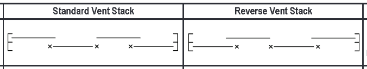

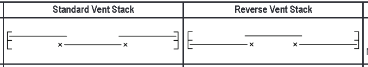

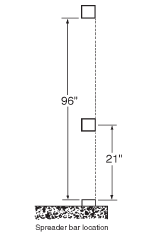

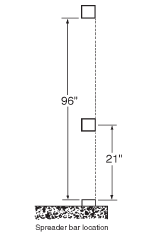

Spreader bars are required on actual unit widths that exceed 30” wide. It is recommended to use 2 spreader bars on units over 60” wide. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

To use this chart with twin and triple units do the following:

Twin unit: divid opening width by 2 then locate that size on the chart above

Triple unit: divid opening width by 3 then locate that size on the chart above

Spreader bars are required on actual unit widths that exceed 30” wide. It is recommended to use 2 spreader bars on units over 60” wide. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

To use this chart with twin and triple units do the following:

Twin unit: divid opening width by 2 then locate that size on the chart above

Triple unit: divid opening width by 3 then locate that size on the chart above

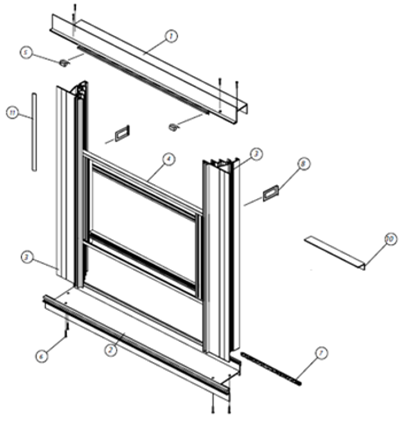

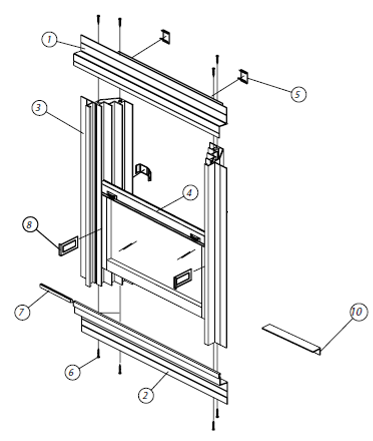

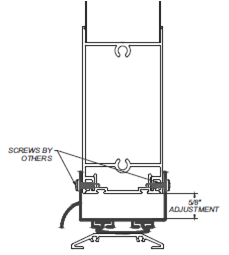

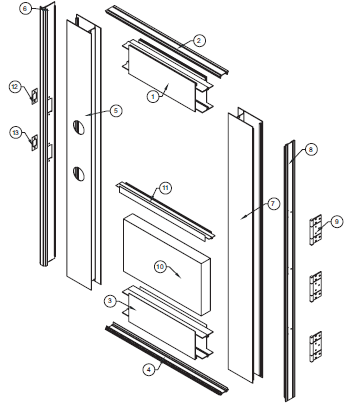

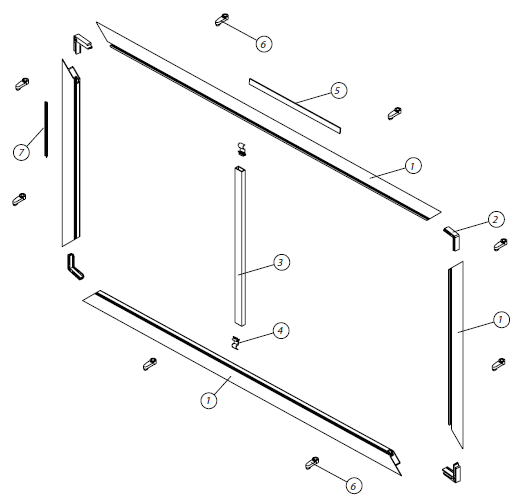

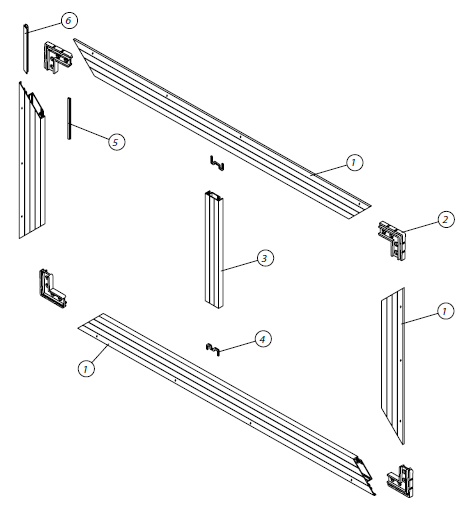

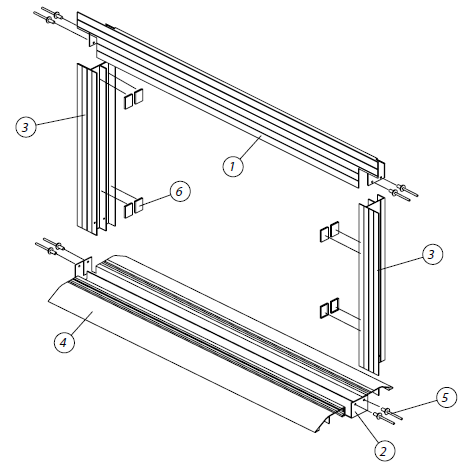

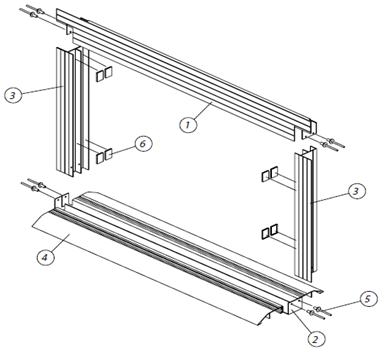

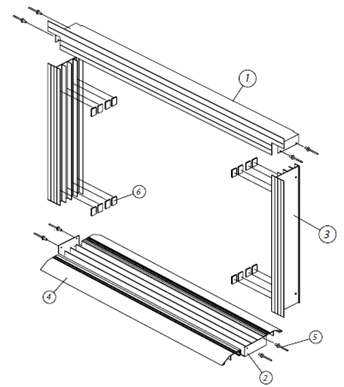

4V60 Outside Mount Frame Assembly

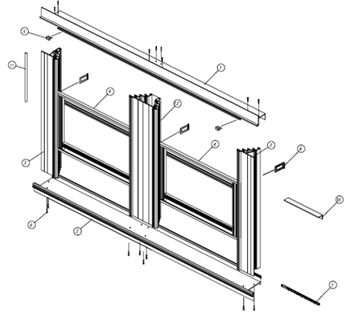

4V60 Outside Mount Frame - Twin Assembly

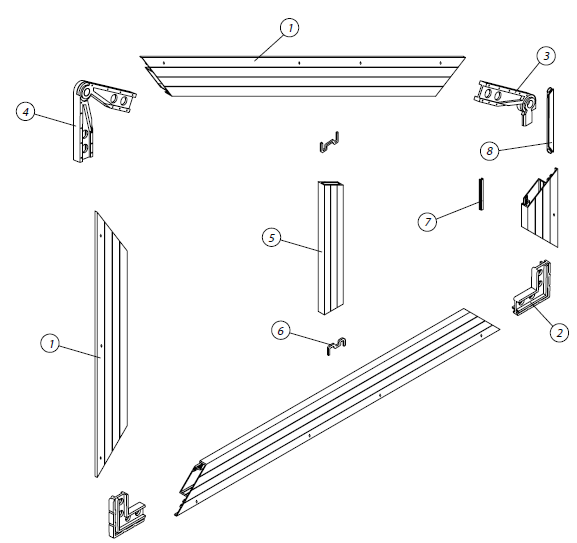

4V60 Inside Mount Frame Assembly

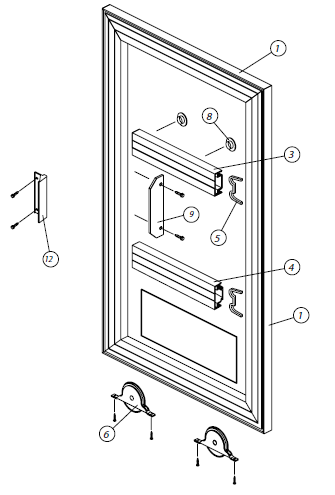

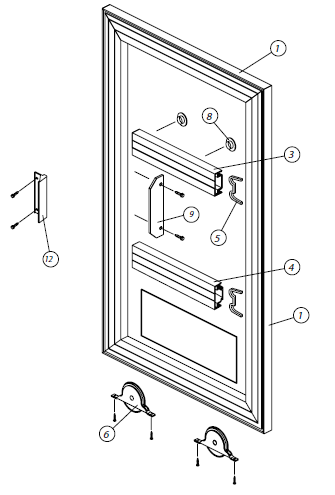

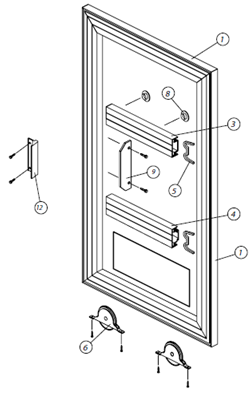

4V60 Vent Assembly (OSM/ISM)

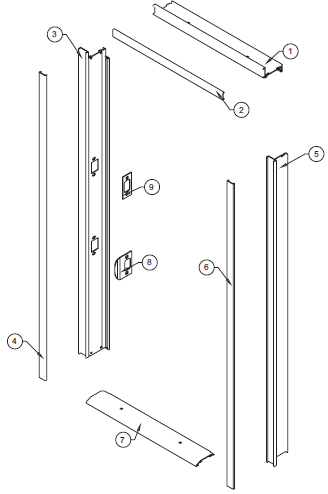

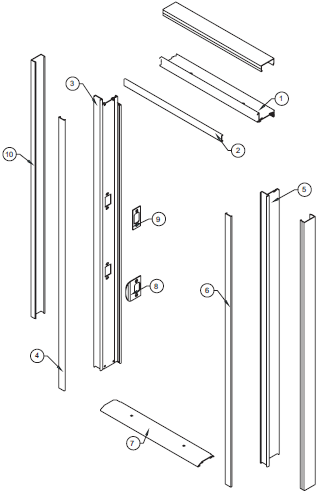

4V60 Parts

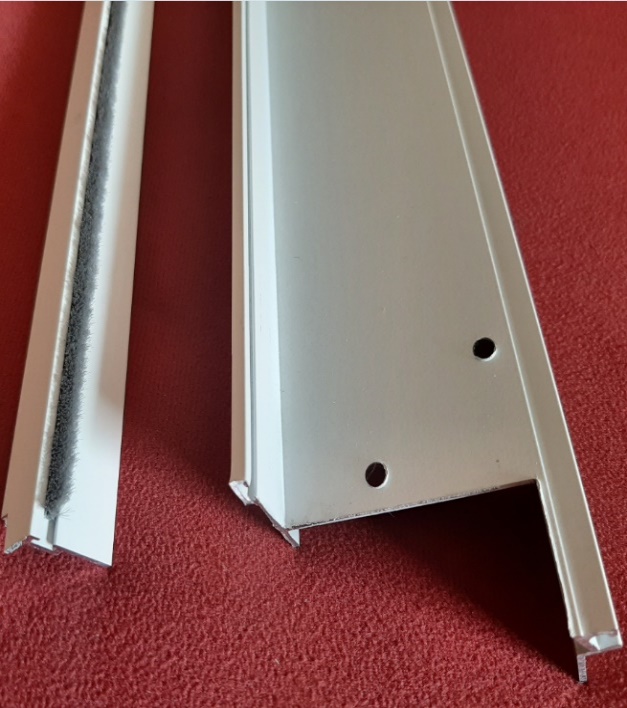

Frame Jamb (OSM)

Frame Head (OSM)

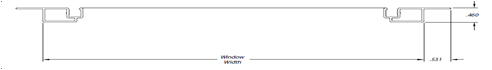

Frame Sill (OSM)

Frame Jamb (ISM)

Frame Head (ISM)

Frame Sill (ISM)

Twin/Triple (intermediate) Frame Jamb

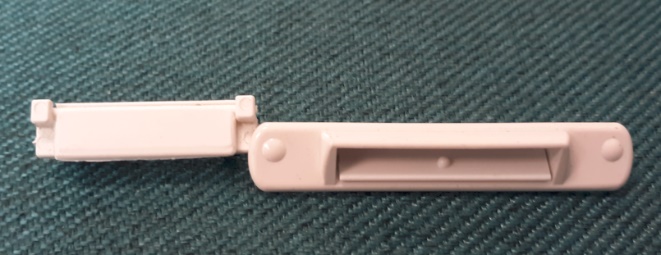

Top Vent Clip

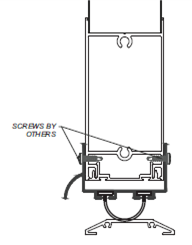

Installation Clip

This clip is installed to the top vent. The dealer uses this as a guide for the install screws, top screw goes in this location, you then lower vent #1 down to interlock with vent #2, next screw goes there, you then lower vents #1 & #2 down to interlock with vent #3, etc.

Track Filler Angle

This filler is installed into the main frame prior to assembly. It is used when the unit is only ordered with two or three vents to fill the sill, so dirt does not build up in the unused tracks.

Frame Assembly Screw (#8 x .500)

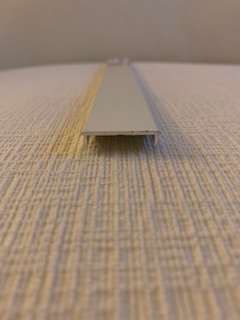

Flat Spline (used to roll screen into the main frame)

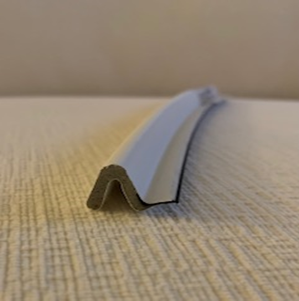

Jamb Fin Seal (vent)

Sill Track Filler Weatherstripping

Fin Seal Weatherstripping (used on main frame sill)

ISM Screen Spacer **

ISM Pop-Rivet (colour matched) **

** Used with screens attached only

This is how the top of the vent is assembled

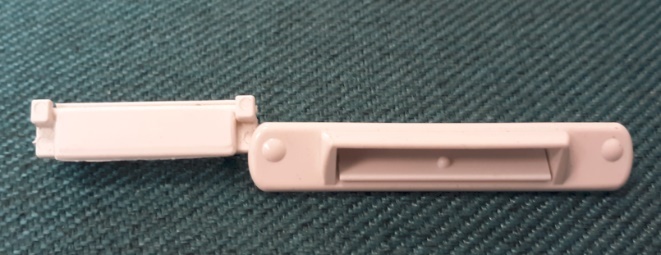

Slide Bolt Assembly (colour matched to vent extrusion)

Thumb Latch (colour matched to vent extrusion)

Spring Cap Assembly (colour matched to vent extrusion)

Vent Spacer (always black)

Spring Stop Block (front)

Spring Stop Block (back)

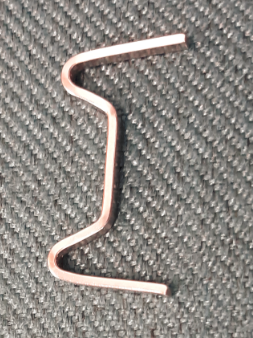

Spreader Bar Clip

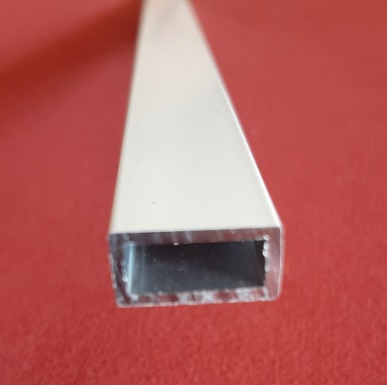

Spreader Bar

Vent Assembly Square Drive Screw (#8 x .500)

Rigid V-Spline (used to roll glazing material or screen into vents)

4V60 Goody Bag

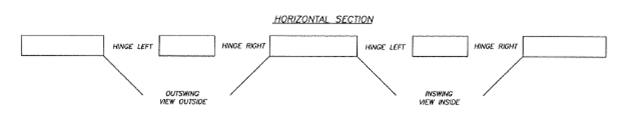

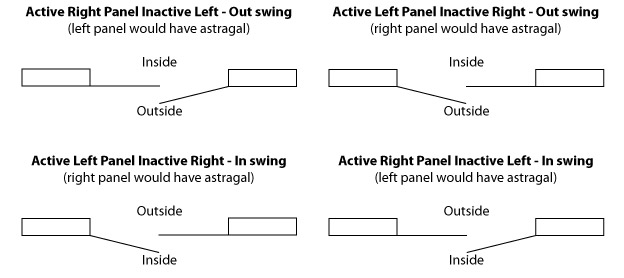

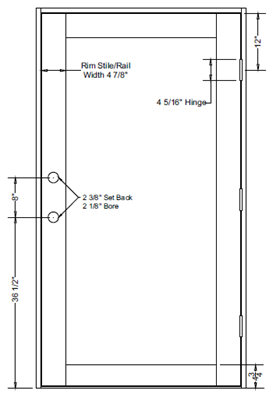

Double Door Hinge and Swing

All doors are viewed from the direction of swing.

Inactive panels would swing open in the same direction of the active panel when the flush bolts on the astragal are unlocked.

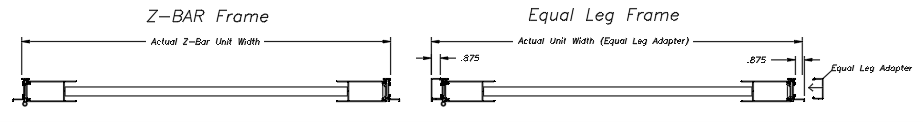

Actual size measurement is preferred.

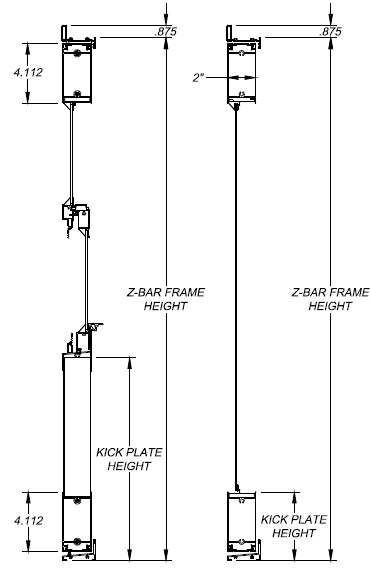

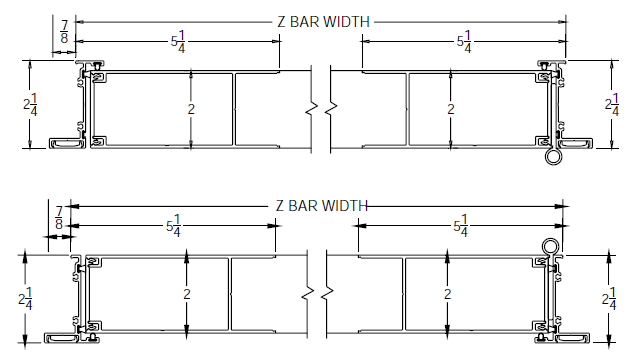

Box equal leg adapter can be added to Z-bar Frame.

Kickplate dimensions are always measured from the bottom of the opening to the top of the kickplate.

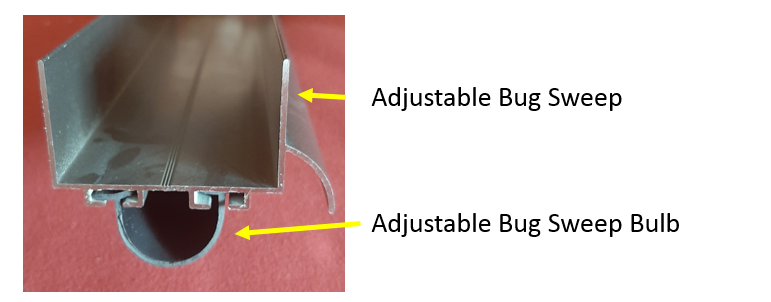

Heights calculated here are for a slab with no adjustable bug sweep options.

**Adjustable Bug Sweep is not available with a double CD90 configuration at this time**

Spreader bars are required when the window insert exceeds 30” wide. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

Standard sizes are:

Custom sizes are available by quote only. Call 1 800 567 5872.

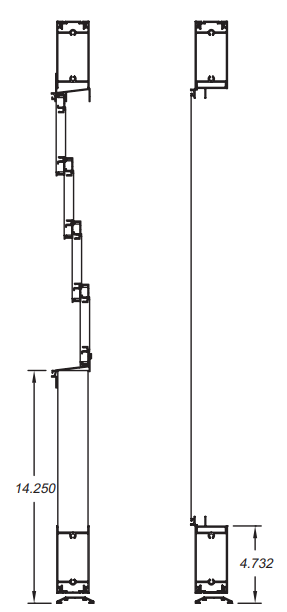

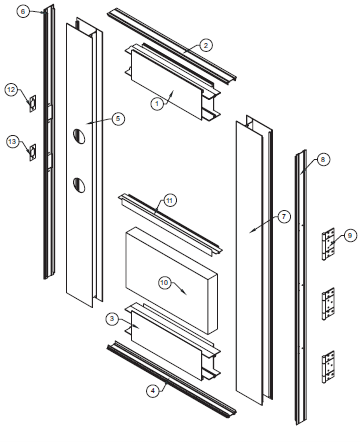

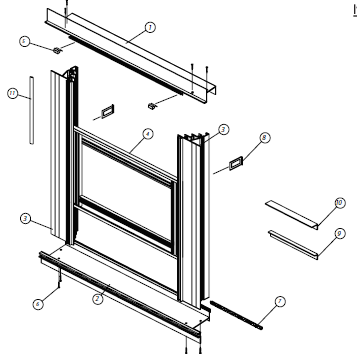

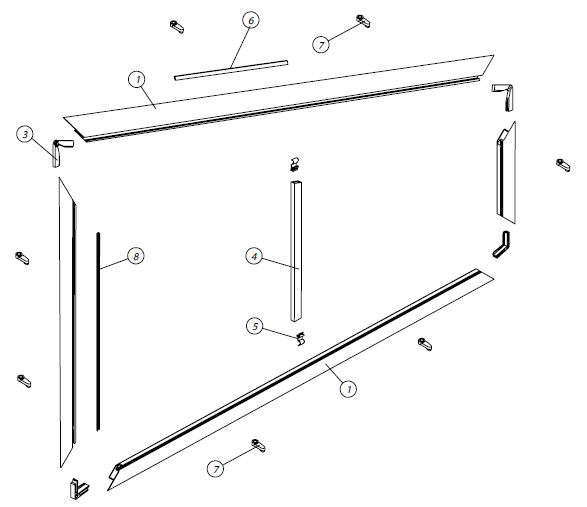

CD90 Z-Bar Frame Frame Assembly (single & double)

CD90 Box Frame Assembly (single & double)

CD90 Cabana Door Slab Assembly (single)

CD90 Cabana Door Slab Assembly (double)

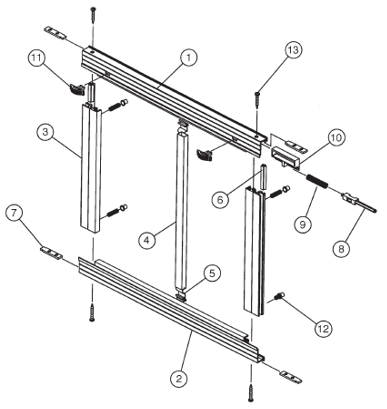

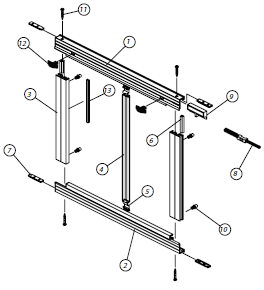

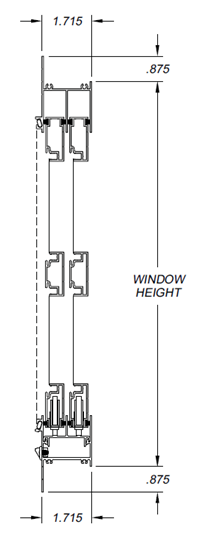

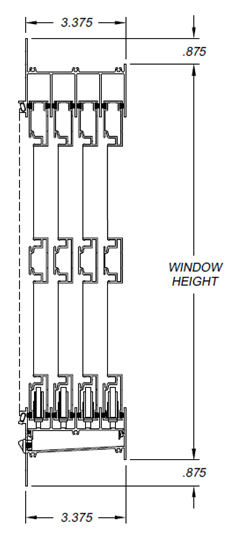

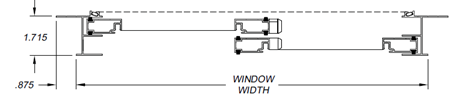

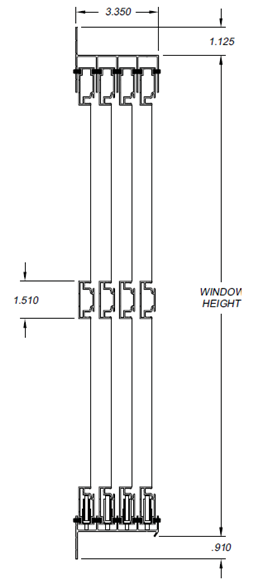

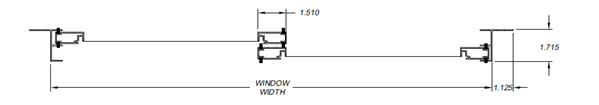

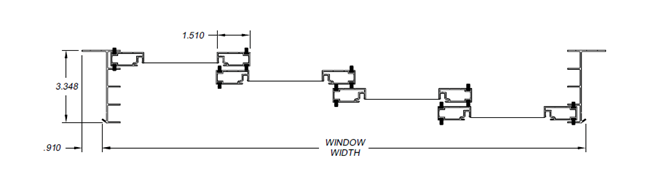

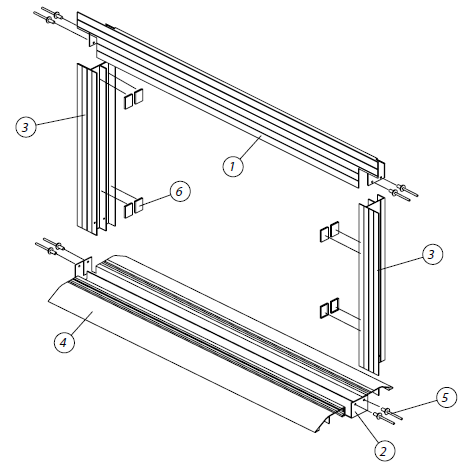

4V60 Vertical Four Track Window Style Assembly

4V60 Vertical Four Track Window Style Vent Assembly

CD90 Fixed Lite Window Style Frame Assembly

CD90 Parts

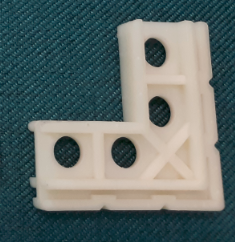

Head/Jamb Equal Leg Adapter

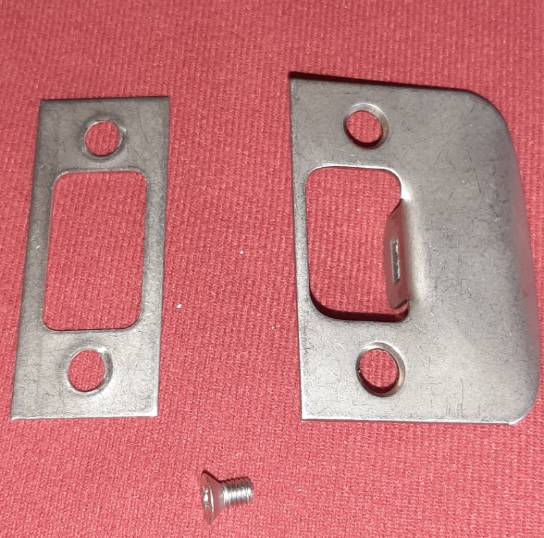

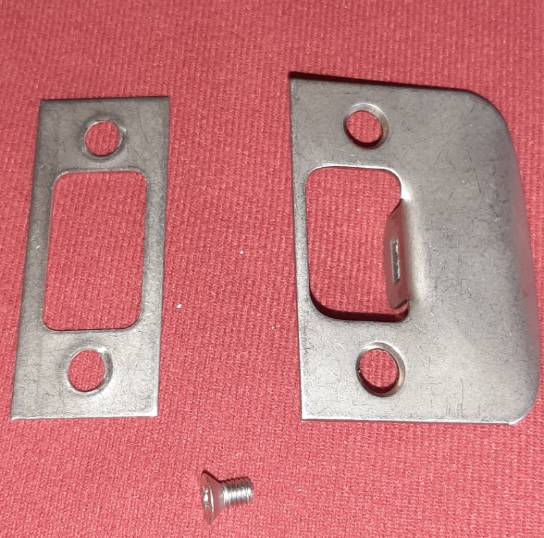

Frame Top/Bottom Backing Plate

Frame Screw Cover

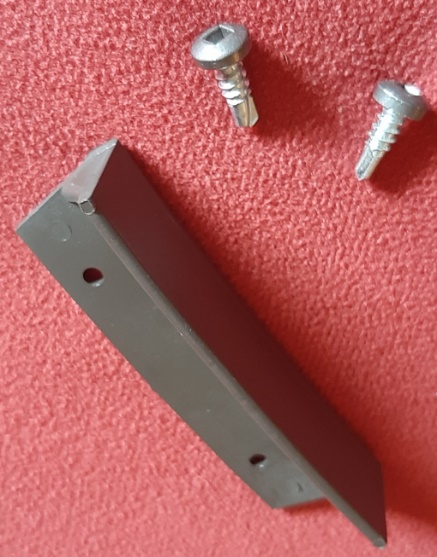

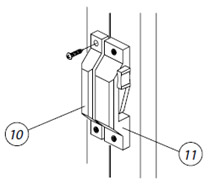

Backing Strike Screw

Deadbolt Striker Backing Plate

Frame Assy Screws (#6 x 3/4" Flat Phillips)

Frame Weatherstrip Bulb

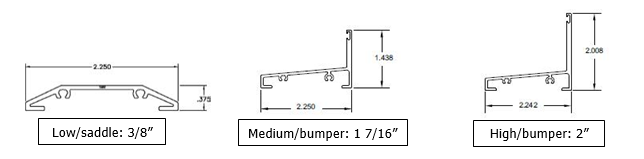

Low/Saddle

Medium Bumper

High Bumper

Adjustable Bug Sweep Bulb

Lock/Hinge Rail Backing Plate

Astragal

Kickplate Cap

Astragal Weatherstripping

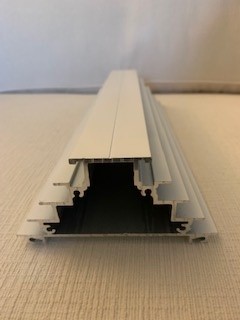

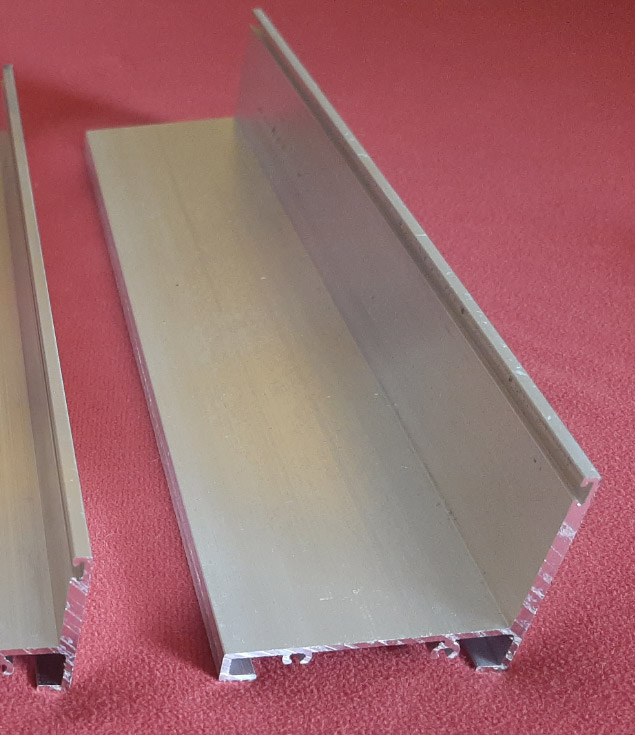

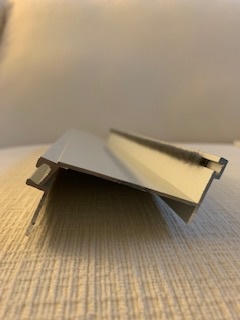

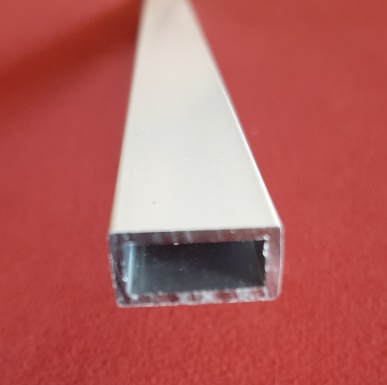

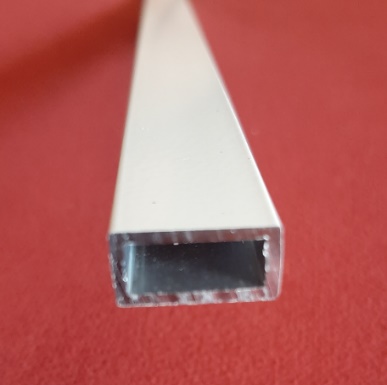

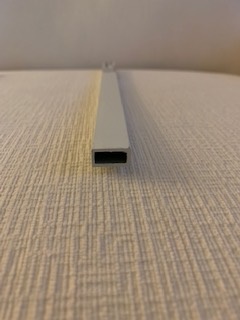

OSM LF20 Insert Frame Material

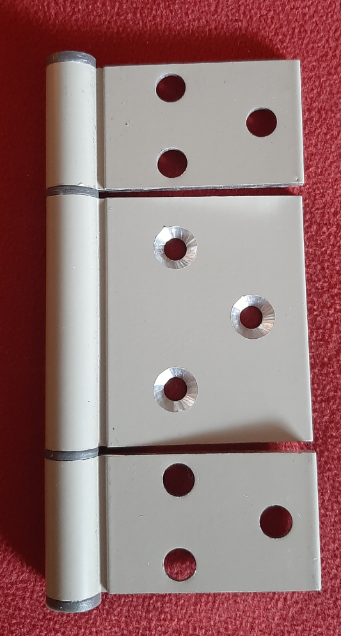

Hinge

Slab Assy Screws (1/4" - 20 x 1")

Installation Screws (come in a kit bag of 15 #10 x 2: Flat Phillips)

Knob Strike Backing Plate

Deadbolt and Lock Strike Plate

Astragal End Seal (for a double door)

Knob and Thumb Turn

Knob and Deadbolt

Knob and Thumb Turn

Knob and Deadbolt

Lever and Thumb Turn

Lever and Deadbolt

Lever and Thumb Turn

Passage Balboa Lever

Available in Satin Silver & Black Suede

Passage Tylo Knob

Available in Satin Silver, Antique Brass, Polished Brass, & Polished Chrome

Deadbolt Lock Set

Features SmartKey Security™, which protects against advanced break-in techniques and allows you to re-key your lock yourself in seconds. SmartKey Security™ re-key technology is compatible with Kwikset (KW1) keyway or (SC1) keyway options. Deadbolt is operated by key outside, thumb turn inside. Comes with 2 keys.

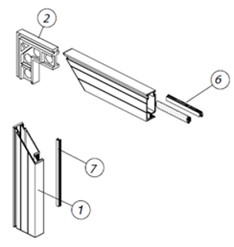

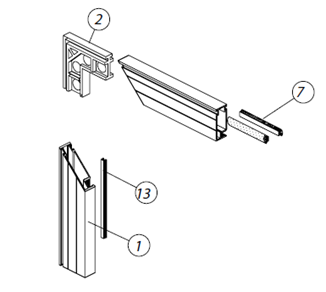

LF20 Parts

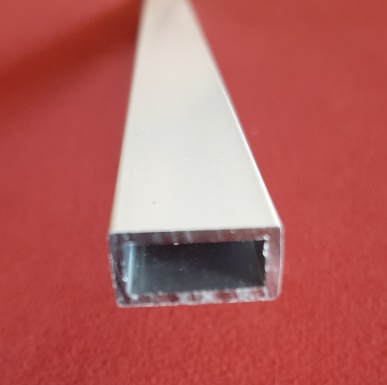

LF20 Frame - Head/Sill/Jamb

Swivel Clip

Rivet (colour matched)

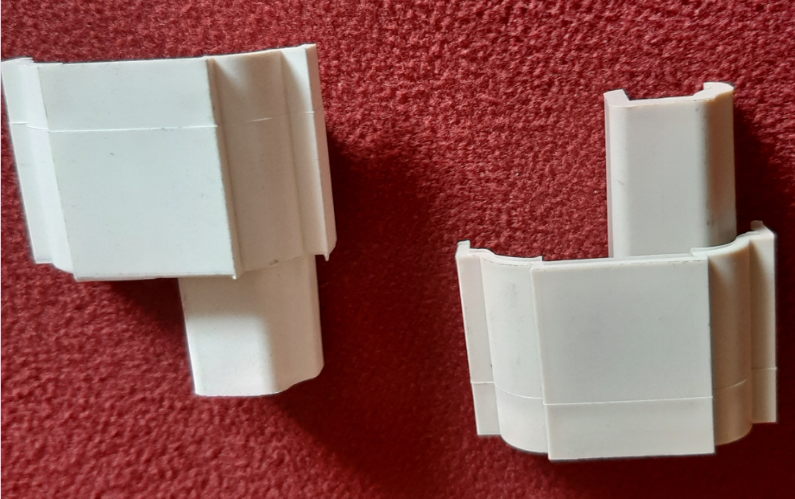

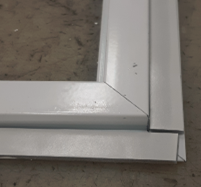

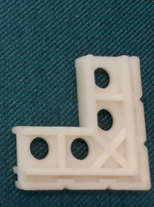

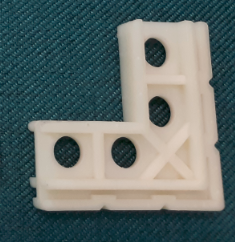

Female Adjustable Corner Key

Male Adjustable Corner Key

Standard Corner Key

Spreader Bar Clip

Spreader Bar

Rigid V-Spline

4V60 Parts

4V60 Frame Jamb (OSM)

4V60 Frame Head (OSM)

4V60 Frame Sill (OSM)

Top Vent Clip

Track Filler Angle

This filler is installed into the main frame prior to assembly. It is used when the unit is only ordered with two or three vents to fill the sill, so dirt does not build up in the unused tracks.

Frame Assembly Screws (this is the main frame assembly screw - #8 x .500)

Flat Spline (used to roll screen into the main frame)

4V60 Jamb Fin Seal (vent)

4V60 Sill Track Filler Weatherstripping

Fin Seal Weatherstripping (used on main frame sill)

This is how the top of the vent is assembled

Slide Bolt Assembly (colour matched to vent extrusion)

Thumb Latch (colour matched to vent extrusion)

Spring Cap Assembly (colour matched to vent extrusion)

Vent Spacer (always black)

Spring Stop Block (back view)

Spring Stop Block (front view

Spreader Bar Clip

Spreader Bar

Vent Assembly Square Drive Screw (vent assembly screw - #8 x .500)

Rigid V-Spline (used to roll glazing material or screen into vents)

4V60 Goody Bag

Spreader bars are required on actual unit size that exceeds 42” in width or height. If height is greater than width the unit will get a horizontal spreader. If Width is greater than height the unit will get a vertical spreader. Temporary spreaders are available for shipping and handling purposes. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

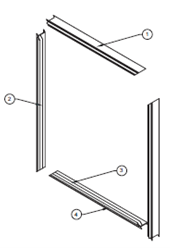

LF20 Standard Lip Frame Assembly (fixed lite)

LF20 Standard Lip Frame Assembly (trapezoid)

LF20/LS20 Parts

Frame - Head, Sill, Jamb

Foam Tape Applied

Swivel Clip

Rivet (colour matched)

Female Adjustable Corner Key

Male Adjustable Corner Key

Standard Corner Key

Spreader Bar Clip

Spreader Bar

Rigid V-Spline

Spreader bars are required on actual unit size that exceeds 60” x 48” or 48” x 60” in width or height. If height is greater than width the unit will get a horizontal spreader. If Width is greater than height the unit will get a vertical spreader. Temporary spreaders are available for shipping and handling purposes. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

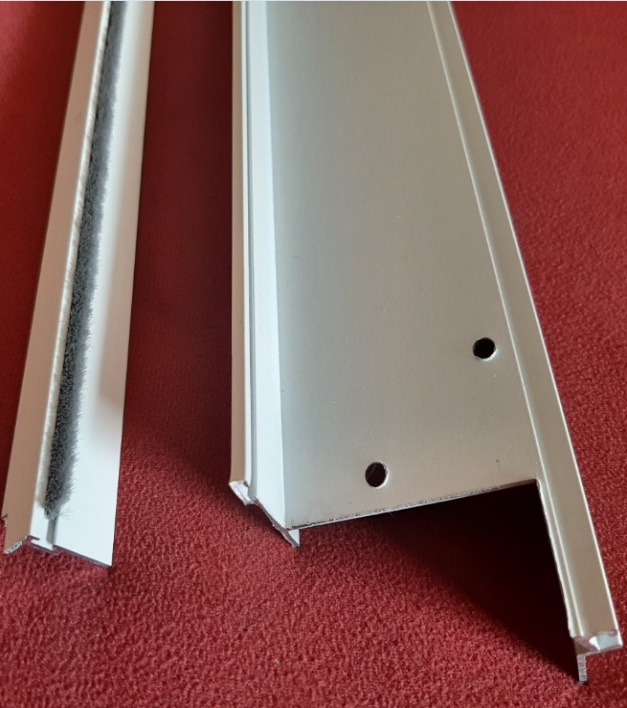

HLF20 Heavy Duty Lip Frame Assembly (fixed lite)

HLF20 Heavy Duty Lip Frame Assembly (trapezoid)

HLF20/HLS20 Parts

Heavy Duty Frame - Head, Sill, Jamb

Bulb Weatherstripping

Bulb Weatherstripping

Spreader Bar Clip

Spreader Bar

Rigid V-Spline

Female Adjustable Corner Key

Male Adjustabel Corner Key

Standard Corner Key

For use on really small legged shapes

Spreader bar(s) are required on actual unit heights that exceed 48” tall. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

Maximum actual unit width: 192".

Spreader bar(s) are required on actual unit heights that exceed 48” tall. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

Units that exceed 192" actual unit width, will be spliced. See guideline for details.

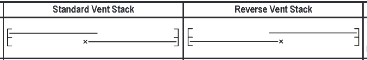

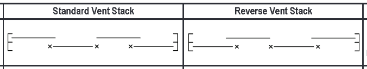

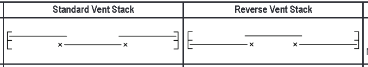

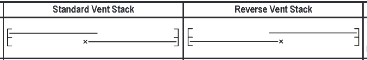

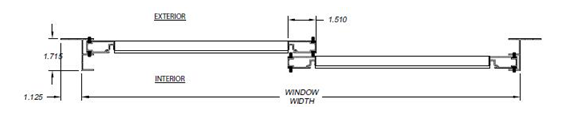

SS10 Outside Mount Frame Assembly

SS10 Outside Mount Vent Assembly

SS10 Inside Mount Frame Assembly

SS10 Inside Mount Vent Assembly

Available Colours: White, Beige, Pebble Khaki, Bronze, Black

ISM Head 2T

ISM Jamb/Sill 2T

ISM 4T Head

OSM 2T Head

OSM 2T Sill

OSM 2T Sill Cover

OSM 2T Sill/Sill Cover Combined

OSM 4T Head

OSM 4T Jamb

OSM 4T Sill

OSM 4T Sill Cover

OSM 4T Sill/Sill Cover Combined

Lip Frame Head/Sill/Jamb

Top/Bottom/Side Rail (vent/head/jambs/sill)

OSM Lip Frame Spreader Bar

Spreader Bar Clip

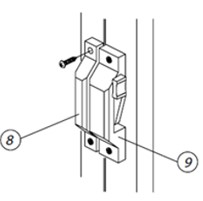

Latch Assembly

Lock installed above spreader bar clip

Spreader Bar

Angle (installed where vents meet on same track)

Frame Assy Screws (used on OSM) #6x3/4"

ISM/OSM Weep Hole Covers

Lip Frame Vent Corner Key

Stainless Steel Neoprene Roller and Wheel Screw

Pull Handle with 1/2" Tek Screw

Frame Bumper

Weatherstrip - Jamb/Vent

Rigid V-Spline

Rivet - used on ISM Frame Assembly w/Screens

2T/4T Gasket Sill - OSM

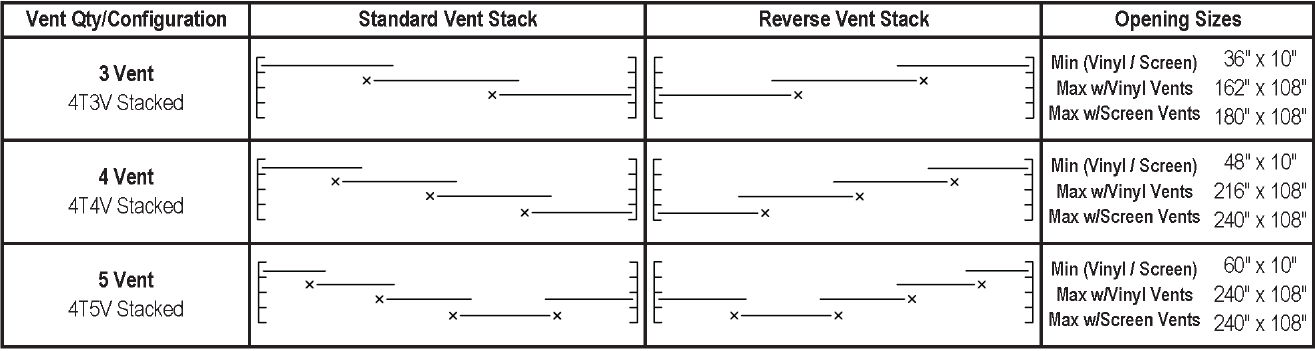

Spreader bar(s) are required on actual unit heights that exceed 48” tall. If spreader bar is required based on size and “NONE” is selected, the warranty is void.

Maximum actual unit width: 192".

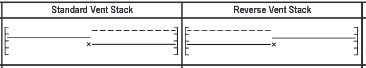

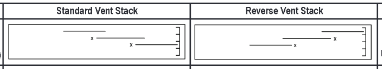

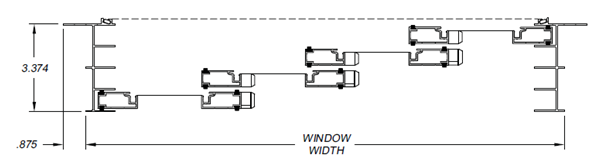

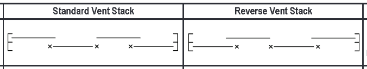

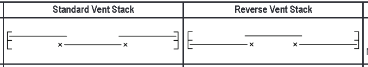

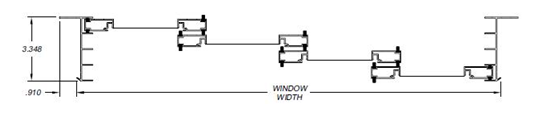

SS30 2-Track Frame Assembly

SS30 4-Track Frame Assembly

SS30 Vent Assembly

Available Colours: White, Beige, Pebble Khaki, Bronze, Black

ISM - 2T Head/Jamb No Flange

ISM - 4T Floor Sill No Flange

ISM - 2T Head

ISM - 2T Jamb/Sill

ISM - 4T Head

ISM - 4T Sill w/Flange

Top/Bottom/Side Rail (vent/head/jamb/sill)

Spreader Bar w/Kickplate Groove

Threshold both Sides

Threshold 1-Side of Sill

Spreader Bar Clip

Latch Assembly

Lock installed above spreader bar clip

Spreader Bar

Vent Angle (installed where vents meet on same track)

Frame Assy Screws #6 x 3/4"

Weephole Covers

Thumb Pull

Vent Corner Key

Stainless Steel Neoprene Roller w/Screws

Pull Handle with 1/2" Tek Screw

Panel Come Along with 3/4" Tek Screw

Frame Bumper

Weatherstrip - Jamb/Vent

Rigid V-Spline

Rivet